Intel 18A is now in full production!

Intel has announced the full production of its Intel 18A process. Both the client Panther Lake series and the server Clearwater Forest processors will utilize this first 2nm-class process node developed and manufactured in the United States. Produced at Fab 52 in Arizona, these products will be released in subsequent releases, fulfilling Intel's previously stated commitment to mass production of the 18A process in the second half of 2025.

Panther Lake, built on the Intel 18A process, scalable AI PC performance

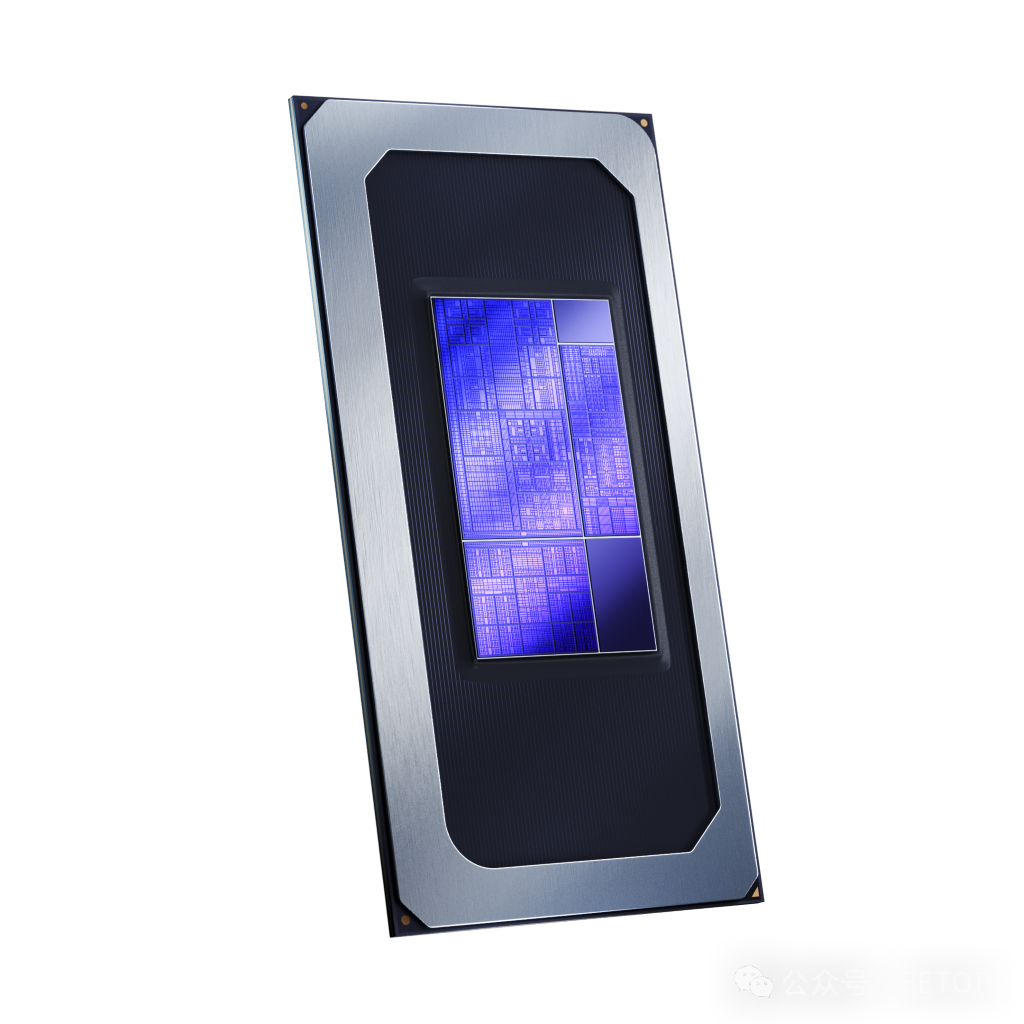

The new generation of client Intel Core Ultra processors (Series 3), codenamed Panther Lake, are Intel's first products to utilize the Intel 18A process, hailed as the most advanced semiconductor process technology developed and manufactured in the United States. This represents a key milestone for Intel in strengthening its U.S. technology and manufacturing leadership and building a resilient semiconductor supply chain.

An Intel manufacturing technician holds an Intel Core Ultra processor (Series 3) (codenamed Panther Lake) manufactured using the Intel 18A process.

Intel stated that Intel Core Ultra processors (Series 3) are expected to begin shipping in late 2025 and enter the market in January 2026. Panther Lake is the first client system-on-chip (SoC) to utilize Intel's 18A process technology and targets a wide range of markets, including consumer and commercial AI PCs, gaming devices, and edge computing solutions.

Panther Lake utilizes a scalable multi-chiplet architecture, providing partners with unprecedented flexibility across various form factors, applications, and price points. In terms of performance, Panther Lake is designed to achieve Lunar Lake-level energy efficiency and Arrow Lake-level performance.

Panther Lake's key performance improvements and features include up to 16 new performance cores (P-cores) and efficiency cores (E-cores), delivering over 50% higher CPU performance than the previous generation. Additionally, the new Intel Arc GPU, with up to 12 Xe cores, also delivers over 50% higher graphics performance than the previous generation. The balanced XPU design enables higher levels of AI acceleration, delivering platform computing performance of up to 180 TOPS (180 trillion operations per second).

Panther Lake, Intel's first product using the Intel 18A process.

Beyond the PC market, Panther Lake will also extend its reach into edge computing applications, such as robotics. Customers can leverage Panther Lake's computing and AI perception capabilities with the new Intel Robotics AI software suite and reference development kit to quickly develop cost-effective robots. Panther Lake will enter mass production in 2025, with the first product expected to ship before the end of the year.

Clearwater Forest: Bringing Efficiency and Scale to Modern Datacenters

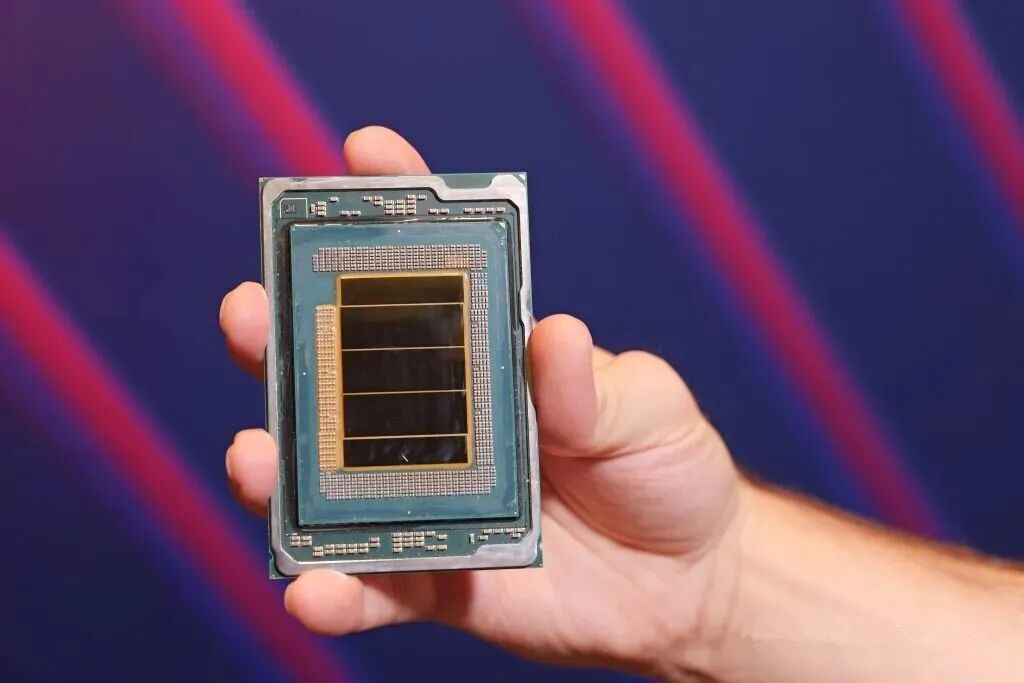

In addition to its client-side offerings, Intel also announced the release of the Xeon 6+, the first server processor using the Intel 18A process, codenamed Clearwater Forest. This new generation of efficiency-core processors is touted as Intel's most efficient server processor to date and is expected to launch in the first half of 2026.

Intel showcased the Intel Xeon 6+ processor (codenamed Clearwater Forest) manufactured using the Intel 18A process at the 2025 Intel Technology Tour.

Intel stated that Clearwater Forest is tailored for hyperscale data centers, cloud service providers, and telecom operators, helping enterprises scale workloads, reduce energy costs, and drive smarter service operations. Key features of Clearwater Forest include up to 288 efficiency cores, a 17% increase in instructions per cycle (IPC) over the previous generation, and significant improvements in density, throughput, and energy efficiency.

Intel 18A is the first 2nm-class process node developed and manufactured in the United States.

Regarding the Intel 18A used in both the Panther Lake and Clearwater Forest product lines, Intel emphasized that this is the first 2nm-class process node developed and manufactured in the United States, representing a symbol of American technology setting new industry standards. Compared to the previous generation Intel 3 process, Intel 18A delivers up to 15% higher performance per watt and 30% increased chip density. This process node completed R&D and manufacturing validation at Intel's Oregon facility and is currently in early production, with volume production in Arizona underway.

Fabrication technicians at Intel's new Fab 52 in Chandler, Arizona.

Intel explained two key innovations in the Intel 18A process. The first is the use of RibbonFET, Intel's first new transistor architecture in over a decade, which enables better scaling and more efficient switching, significantly improving performance and energy efficiency. It also incorporates PowerVia, an innovative backside power supply technology for improved current and signal transmission efficiency.

Furthermore, Intel's advanced packaging and 3D chip stacking technology, Foveros, enables multiple chip modules to be stacked and integrated into advanced single-chip (SoC) designs, providing greater system flexibility, scalability, and performance. Intel 18A will serve as the foundation for at least three generations of Intel client and server products.

Arizona Fab 52 will become a key engine for domestic U.S. manufacturing.

Products including Panther Lake and Clearwater Forest, as well as multiple generations of Intel's 18A process, are produced at the state-of-the-art Fab 52 in Chandler, Arizona. Fab 52 is Intel's fifth large-scale production fab at its Ocotillo, Arizona, campus, and is responsible for producing the nation's most advanced logic chips.

Intel CEO Lip-Mo Tan, wearing a cleanroom protective suit, toured Intel's Fab 52 in Chandler, Arizona.

The construction of Fab 52 is a key component of Intel's $100 billion investment to expand its U.S. operations. With advanced R&D and production capabilities in Oregon, large-scale manufacturing in Arizona, and packaging operations in New Mexico, Intel is uniquely positioned to support key national priorities and provide strategic capacity to Intel's wafer customers. Fab 52 builds on Intel's 56 years of R&D and manufacturing expertise in the United States, marking a significant milestone in establishing a trusted, advanced U.S. wafer foundry for the AI era.

Fab 52, a new wafer foundry in Chandler, Arizona

Intel CEO Lip-Bu Tan stated, "We are entering an exciting new era of computing, fueled by significant advances in semiconductor technology that will profoundly impact the coming decades. Furthermore, Intel's next-generation computing platforms, combined with leading-edge process technology, manufacturing, and advanced packaging capabilities, will be key drivers of innovation, helping to build a new Intel." Tan also noted that the United States has always been a hub for Intel's most advanced R&D, product design, and manufacturing. "We are proud to continue this legacy, expanding our U.S. operations and bringing our innovations to market."