Murata's silicon capacitors join the field of artificial intelligence

With the rapid adoption of artificial intelligence in cloud, edge computing, and terminal devices, demand for high-performance electronic components continues to rise. Against this backdrop, Murata, a global leader in MLCCs, is leveraging its silicon capacitor technology to deepen its presence in the AI market and establish a differentiated advantage.I. Strategic Approach to AI

Recently, James Huang, General Manager of Murata's Computing Market Business Group, and Olivier Gaborieau, Senior Product Line Manager at Murata, gave exclusive interviews to Electronic Innovation Network and other media outlets.

Huang stated that Murata completed an organizational restructuring since October of last year, shifting its business management from regional to horizontally integrated to more quickly respond to global AI market demand. The company sees the AI application market as a growth opportunity, encompassing multiple areas including PCs, servers, switches, and optical modules, with accelerator cards and high-frequency optical modules as key development areas.

He stated that Murata's vision is to become a "best solution provider," driving the development of the electronics industry and society by accelerating the evolution of computing technology. Murata emphasizes leveraging its global network and resources to contribute to the AI ecosystem and ensure the provision of high-value-added component solutions for a wide range of customers.

II. Silicon Capacitor Technology: A Core of Differentiation

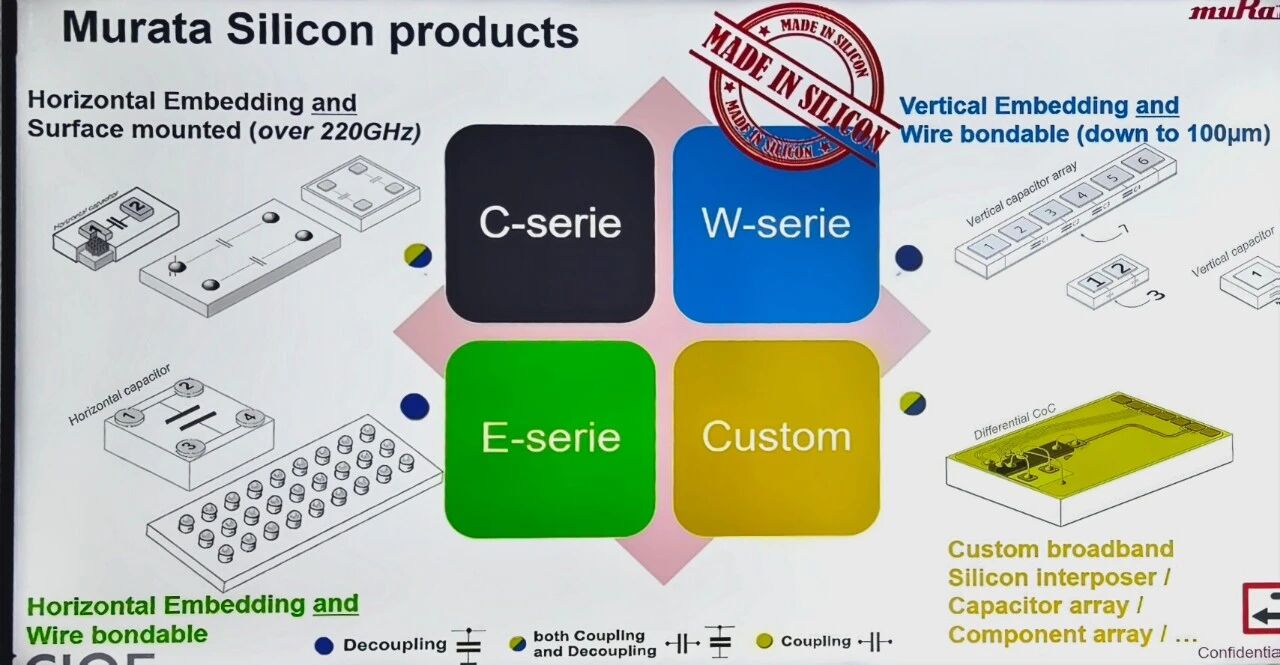

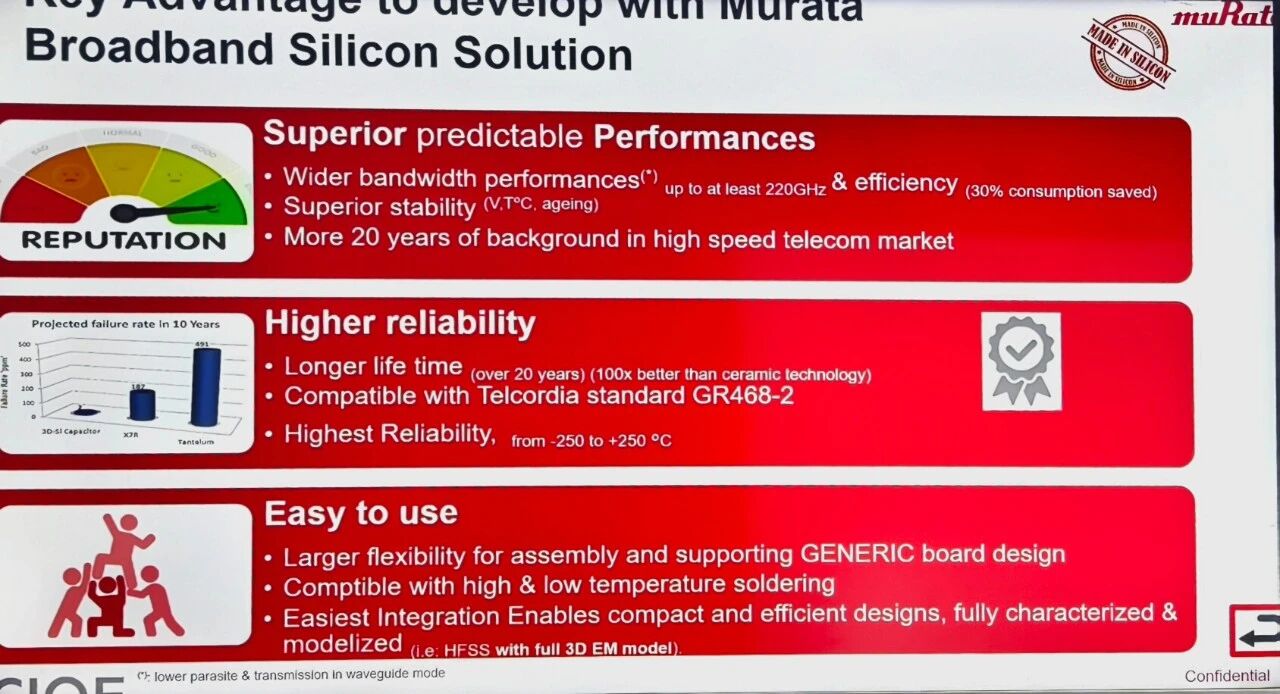

Olivier Gaborieau stated that Murata's silicon capacitor technology, after over two decades of research and development and optimization, has progressed from the laboratory stage to global mass production. Its core advantages are primarily reflected in the following aspects:

High Density and Miniaturization

Murata utilizes a three-dimensional (3D) structural design, achieving a capacitance density of up to 2.5 microfarads per square millimeter and a thickness of less than 40 microns. Compared to traditional aluminum electrolytic or ceramic capacitors, silicon capacitors offer significant advantages in space utilization and integration, making them particularly suitable for high-density AI accelerator cards and optical module applications.

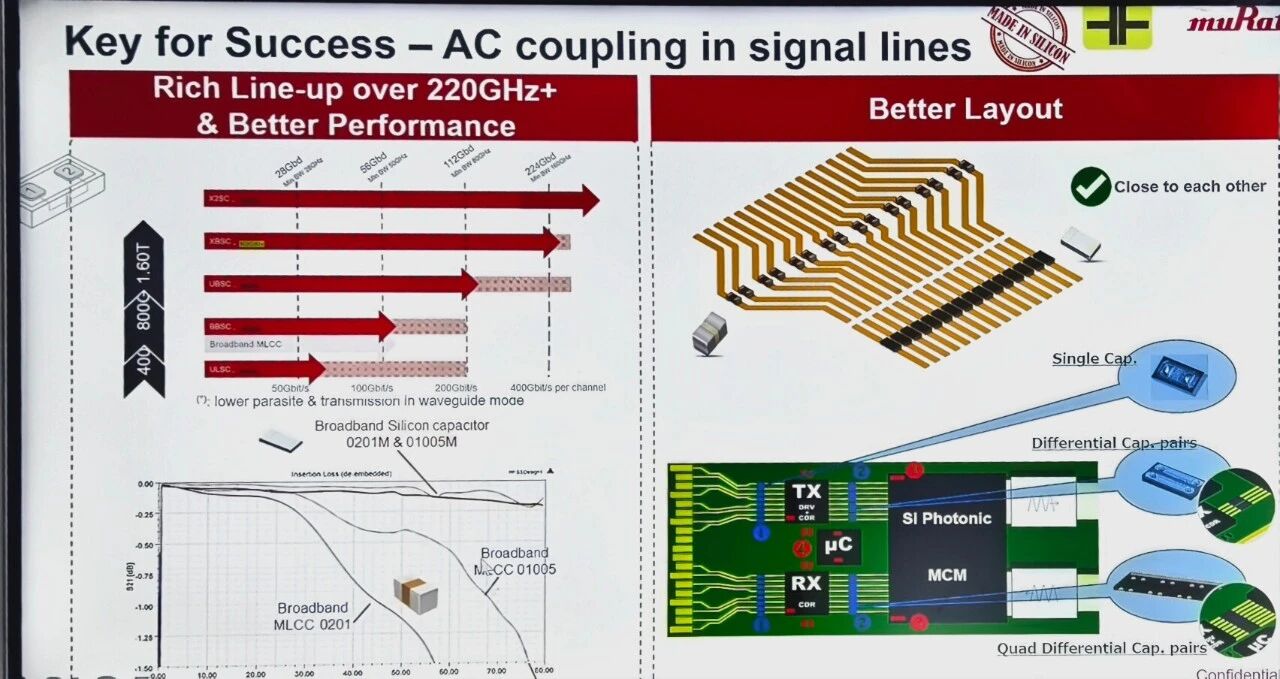

Wideband Characteristics and High-Frequency Adaptability

Olivier Gaborieau noted that the current series of capacitors supports bandwidths up to 220kHz, sufficient to meet the high-speed signal transmission requirements of optical modules, including 1.6T and even future 3.2T. Furthermore, the products support high-voltage applications, with voltage tolerance exceeding that of competing products. Low Power Consumption and High Reliability

He stated that power consumption and temperature management are particularly critical in data centers and communication modules. Murata's silicon capacitors can achieve up to 70% power savings and feature a temperature resistance of 500°C, ensuring long-term stable operation and a lifecycle of over 10 years, far exceeding the market average.

Global Manufacturing and Supply Chain Advantages

Olivier Gaborieau noted that Murata currently has two dedicated silicon capacitor production lines in France. Murata also operates factories in China, Southeast Asia, and other locations producing a variety of components to be close to key customers and ensure supply chain security. A multi-factory strategy can ensure uninterrupted supply of critical components in the event of geopolitical or policy changes.

III. Differentiated Value in AI Applications

Silicon capacitors are small, highly stable capacitors manufactured using thin-film semiconductor technology. Their key characteristic is that their capacitance remains stable despite applied voltage and temperature fluctuations. Manufactured using semiconductor processes and silicon as a raw material, silicon capacitors offer advantages such as high density, low thickness, high reliability, and low loss (ESL and ESR). They are widely used in smartphones, wearable devices, and advanced communications equipment.

Silicon capacitors offer advantages such as high stability, high reliability, high density, low thickness, low loss, and no piezoelectric effect. Traditional capacitors (such as MLCCs) are susceptible to temperature and voltage fluctuations, resulting in capacitance variations, requiring consideration of capacitance derating during design. Silicon capacitors, however, utilize semiconductor processing technology, offering significant advantages in capacitance stability, size, and reliability,

significantly simplifying design and reducing component count.

Furthermore, silicon capacitors have an operating temperature range of an astonishing ±250°C! They are ideally suited for power-hungry AI servers!

Olivier Gaborieau noted that for accelerator cards for AI training and inference, silicon capacitors offer a high-density, low-power solution, enabling more compact board-level designs while reducing power consumption and thermal management challenges. Murata capacitors currently support the broadband requirements of high-speed optical modules, ensuring stable performance in data centers and communications equipment at high transmission speeds. In the optical module sector, Murata offers a wide range of products, including surface mount solutions, differential packages, and highly integrated custom solutions. These solutions support data rate increases from 1.6Tbps to 3.2Tbps, while also addressing miniaturization and broadband requirements. Working closely with customers, Murata also provides simulation optimization models and customized technical support to help accelerate product iteration.

In addition, silicon capacitors are not limited to terrestrial data centers. Murata's silicon capacitors can also be used in high-frequency satellite communications and industrial instrumentation, adapting to high-temperature, high-frequency, and high-reliability scenarios.

Huang Youxin stated that Murata provides customers with differential capacitors, miniaturization packages, and free electromagnetic simulation models to help them optimize system designs, achieve "first-pass design success," and reduce development cycles.

IV. Competitive Advantages and Future Outlook

Huang Youxin summarized Murata's silicon capacitors' greatest advantages over competitors: 1. Deep technological expertise: With a R&D cycle exceeding 20 years, the technology is mature and continuously iterated. 2. High integration and reliability: Murata offers high-density, low-profile, broadband, and high-temperature resistant products suitable for a variety of AI application scenarios. 3. Global Supply Chain and Localized Services: A multi-factory, multi-sales network, and R&D center layout ensures customers receive more stable and timely supply and technical support.

From an industry perspective, the rapid growth of the AI and high-performance optical communications markets has posed unprecedented challenges to fundamental components. Silicon capacitors, as core high-frequency, high-density, and low-power components, have technological advancements that directly impact system performance and energy efficiency. Murata has established a distinct differentiated advantage through years of technological accumulation, a global R&D and production presence, and a customized strategy for the AI and optical module markets.

In the era of rapid AI development, hardware innovation often determines the success of technology implementation. Murata's micro-innovations in silicon capacitors not only meet the demands for high speed, low power consumption, and high reliability, but also build customer loyalty through differentiated services. In the future, this tiny component will continue to drive upgrades in the AI computing and optical communications industries, providing critical support for the global digital wave.

In addition to silicon capacitors, Murata's DC-DC power modules are rumored to have also entered the AI server market.

Huang Youxin stated that as demand for AI chips and high-speed communications continues to grow, Murata's silicon capacitors will continue to play a core role in accelerator cards, optical modules, and emerging industrial applications. Murata will also continue to promote product miniaturization, integration, and high-frequency development, providing a differentiated competitive advantage for the global AI industry. (End)