10 billion! Murata plans to expand production and increase production of such components by 3 times!

On June 26, according to the Science and Technology Board Daily, Murata Production Institute planned to invest in about 10 billion yen (about 500 million yuan in about 500 million yuan (about 500 million yuan of RMB 500 million ), Increase the capacity of silicon capacitors to the current level of three times. At present, silicon container applications are limited to medical equipment, but it is expected to expand to applications such as smartphones and servers in the future.Silicon capacitance

Regarding the expansion of silicon capacitors, Murata had previous investment. On March 8th, Murata Production Institute announced that it will invest 50 million euros (about 7.2 billion yen) at its French subsidiary Murata Integrated Passive Slutions (formerly known as IPDIA, located in Kamn City, France). Increase the production capacity of silicon capacitor in 2024.

And this time, according to Japanese industrial news reports, they plan to establish a system that can produce the same silicon capacitors in Kanazawa, Sendai and Finland. They will transform existing thin film devices for the production of high -frequency components (SAW filters).

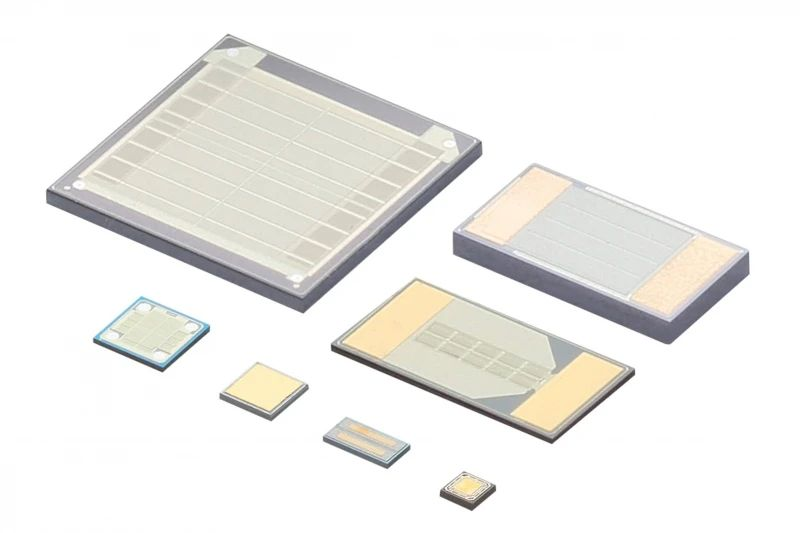

At present, the application of silicon capacitors is mainly concentrated in the fields of implanted medical equipment, but its application scope is expected to expand. For example, with the enhancement of smartphone functions, multiple components need to be installed in a limited space. Murata Production Institute's silicon container is very thin, with a thickness of 0.05 mm, which is suitable for the needs of smartphones.

In addition, as the market demand for semiconductor packaging substrates with semiconductor packaging substrates with semiconductor packaging substrates will also expand with the increase in the increase of artificial intelligence (AI) and data volume. The silicon container can be installed on the back of the packaging substrate. The president of the Murata Production Institute, Nakajima Ruja, said: "Although it has not yet appeared, the demand for packaging substrates will grow in the future."

Murata Production Institute is located in the field of multi -layer ceramic capacitors (MLCC). In order to expand the product line, the company acquired France's IPDIA (now Integrated) in 2016. They plan to promote the standardization of equipment and technology while expanding production capacity.

The advantage of silicon capacitance

Silicon capacitors are components for temporary storage and release of electricity energy. It can also reduce the factors that cause digital device failures such as ESL (equivalent series inductors).

The silicon capacitance is made of silicon material. It is similar to ordinary capacitors. It is also the polar plates up and down. The middle is a dielectric layer. The difference is that the dielectric layer uses silicon material.

Silicon capacitors have many advantages in performance. Because the silicon material is used, the stability of silicon is better, so silicon capacitors also have excellent high -frequency characteristics and temperature characteristics, extremely low bias characteristics, high reliability, and low -back. Silicon capacitors are also smaller and thinner. Standardized silicon capacitors can achieve 100 microns, and customized can achieve 40 ~ 50 microns.

According to data from the market research company Transparence Market Research, the global silicon capacitor market was worth $ 1.58 billion in 2021. From 2022 to 2031, it is expected to grow at 5.4% CAGR (compound annual growth rate). At the same time, according to a study by Mordor Intelligence, the global MLCC market size will reach $ 11.63 billion in 2021. The compound annual growth rate from 2022 to 2027 is 6.03%.