Texas instrument comprehensively reduces prices: from 30% to "no lower limit"

Texas instrument comprehensively reduces prices: from 30%to "no lower limit"According to the Finance News Agency, in May this year, Texas Instruments completely lowered the chip price of the Chinese market, trying to seize more market share at the time before the industry recovers.

From 20%-30%to "no bottom line"

The price reduction news of Texas instruments was reported from the Taiwan market earlier.

In mid-May, there are rumors that TIs in the Taiwan market in China, a significant price reduction of 20 % -30 % for power management ICs, seizing market share.

According to further reports of the microblog, Texas Instruments not only fully lowered the chip price of the Chinese market in May, but the senior management of an analog chip factory said that "TI has no fixed price and bottom line this time."

The analog chip can be divided into general analog chips and special simulation chips. The impact caused by the price reduction of Texas instruments this time, which has a greater impact on universal simulation chips. The general simulation chip includes two categories: power management and signal chain. These two types of chips are the hardest hit areas for the price reduction strategy of Texas instruments, especially the power management chip. Many companies have formed a considerable scale of shipments in this field. The product gradually occupied the high -end market. Therefore, most people in the industry believe that power management chips are the main goal of accurate strikes of Texas instruments.

However, the impact of the market impact on the market that is more decentralized on various types of special simulation chips is uneven. In the dedicated simulation chip market, it can be divided into industrial, automobiles, communications and consumer electronics in different application scenarios. Due to the long chip verification cycle in the industrial and automotive field and scattered categories, the price reduction of Texas instruments is difficult to cause impact in a short time, so it has a limited impact.

Reasons for price reduction: solve business difficulties

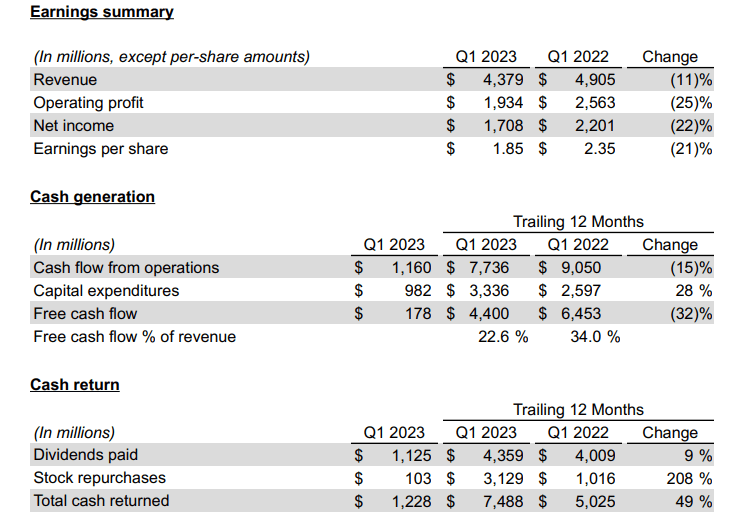

Take a look at the recent financial report released by TI, and you can also understand the decision of a sharp price reduction. In the first quarter of 2023, the company's revenue was US $ 4.379 billion, a year -on -year decrease of 11%. Among them, the simulation chip revenue was US $ 3.289 billion, a year -on -year decrease of 14%, and the revenue of embedded chip treatment chip was 832 million US dollars, an increase of 6%year -on -year. In the first quarter, the number of inventory increased by 38 days from the previous quarter. By 195 days, the inventory amount increased by 531 million US dollars from the previous month to $ 3.3 billion. It can be seen that market demand has declined and inventory has risen sharply. The priority is to solve the dilemma of simulation chip business.

Significant price reduction confidence

Dare to reduce the price significantly, the bottom of the Texas instrument is mainly reflected in two aspects: one is the IDM mode; the other is to build a 12 -inch wafer plant on a large scale.

According to the semiconductor industry's vertical and horizontal analysis, IDM has many advantages in simulating the chip market. Different from digital logic chips (memory, processor, etc.), the simulation chip from design to manufacturing will be more complicated, difficult to form standards, and high degree of correlation with the production line, which makes the simulation chip particularly suitable for the IDM mode. Below, the design of design into products of production lines is higher and cost -controlled, especially for TI, the types and quantities of its simulation chip products are the largest in the world, which can further reduce costs.

Secondly, that is, TI has been expanding 12 -inch wafer fabs for many years, reducing the proportion of 8 -inch wafer production lines.

In the next few years, TI will build 4 12 -inch wafer fabs in Shelman, Texas. Two of them will be constructed in 2022, and mass production will be achieved in 2025. The other two are still planned. Prior to this, TI had built multiple 12 -inch factories in the state, including DMOS6, RFAB1 of Dallas, and RFAB2, Richardson, and RFAB2 in September 2022.

In addition to Texas, TI also has a 12 -inch wafer fab LFAB in LEHI, Utah. The factory was acquired from Micron in October 2021. After transformation, it was invested in mass production in December 2022. It can be produced. Simulation and embedded chips based on the 65nm and 45nm processes.

As a simulated chip manufacturer, it is rare to build so many 12 -inch wafer fabs. The main purpose of TI is to improve the efficiency of the production line and reduce the cost of a single chip.

Traditionally, the simulation chip mostly uses 8 -inch wafers, and even 6 -inch wafers. However, with the development of market applications and demand, and competition intensify, the simulation chip manufacturers, especially the industry ranking, are high -ranking companies. Began to produce analog chips with a 12 -inch wafer production line. The main purpose of this is to improve the efficiency of production capacity and reduce the cost of a single chip, because a 12 -inch wafer can produce more chip products than 8 -inch wafers.

The typical enterprise of this is TI. The company's 12-inch wafer comprehensive cost is 35-40%lower than 8 inches (including depreciation). Well-known manufacturers such as ADI are also doing similar work, but the investment and scale are not as large as TI.

In recent years, after the production and new 12 -inch wafers have been put into production, the output of TI's simulation chip has been further improved, and the production capacity is more efficient. This provides more room for price reduction for TI products to a certain extent.

--- End ---