Murata announced the expansion of production! Will increase the production of such components in Fr

Murata announced the expansion of production! Will increase the production of

such components in France!

On March 8, according to Murata Manufacturing Co., Ltd., Murata Integrated Passive Solutions, the company's

production subsidiary, will build a new 200mm wafer production line in Caen, France, to expand the production capacity

of silicon capacitors. The silicon capacitors produced will be used in implantable medical devices. , telecommunications

infrastructure and mobile phones.

The new production line will produce silicon capacitors

Construction of the new production line will start in spring 2023 and will be installed in the existing building, which is

Construction of the new production line will start in spring 2023 and will be installed in the existing building, which is

expected to create more than 100 jobs between 2023 and 2025.

The new 200mm wafer production line will adopt Murata Manufacturing's unique dielectric formation technology PICS

(Passive Integration Connective Substrate). According to the company, the PICS is characterized by achieving high

performance in terms of electrical characteristics. The products on the new line will achieve high performance and

capacitance, and they will be small in size with a thickness of only 40 μm, mainly targeting the mobile terminal market.

Murata Integrated Passive Solutions is the former French IPDiA acquired by Murata Manufacturing in October 2016.

IPDiA changed its name to Murata Integrated Passive Solutions on April 1, 2017.

Headquartered in Caen, Normandy, France, the company develops and produces 3D silicon capacitors for implantable

medical devices, high-reliability applications, telecommunications infrastructure, automotive and mobile devices. The

company has more than 200 employees in France.After acquiring the former IPDiA, Murata Manufacturing, which specializes in MLCCs, is positioning silicon capacitors

as the "next move."

Murata French silicon capacitor factory

Advantages of Silicon Capacitors

Franck MURRAY, Managing Director of Murata Integrated Passive Solutions said:

"Silicon capacitor technology is becoming more attractive and has gone far beyond niche markets. Furthermore, these

new applications impose stringent requirements in terms of space and yield. This investment is also supported by French

and European ministries support. With this support, we believe we will be able to improve our technology and deliver

greater value to our customers.”

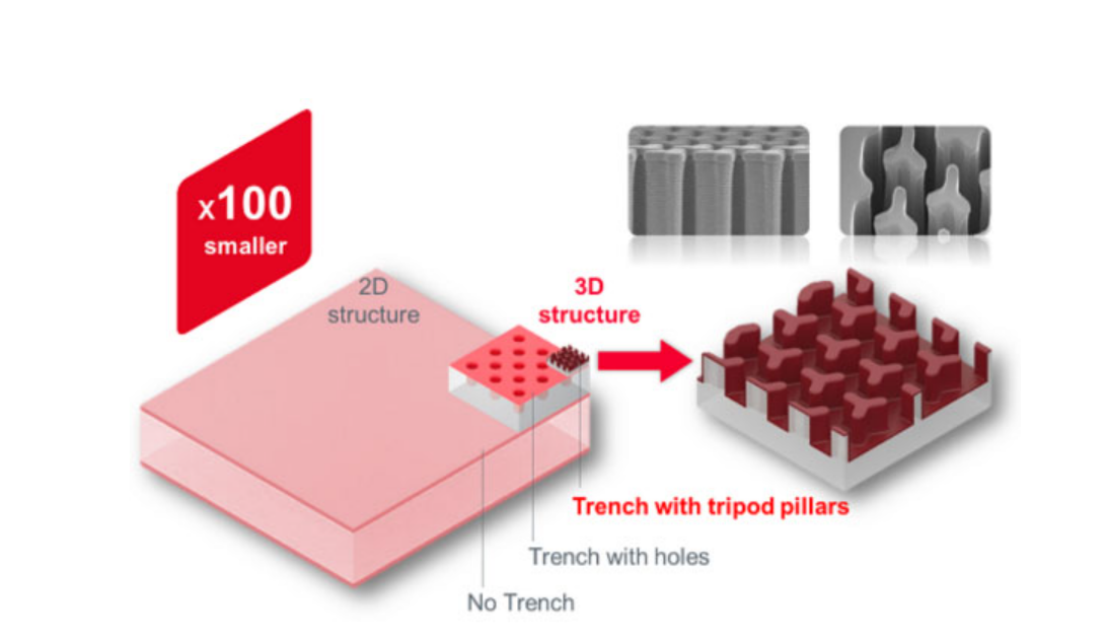

Silicon capacitors are made of silicon material, which is similar to ordinary capacitors, with plates on the top and bottom,

and a dielectric layer in the middle. The difference is that the dielectric layer is made of silicon material.

Silicon capacitors have many advantages in performance. Because the silicon material is used, the stability of silicon is

relatively good, so silicon capacitors also have excellent high-frequency characteristics and temperature characteristics,

extremely low bias characteristics, high reliability, and low-background characteristics. Silicon capacitors are also made

smaller and thinner. Standardized silicon capacitors can be 100 microns, and customized ones can be 40-50 microns.

The internal 3D structure of Murata silicon capacitors

According to market research firm Transparency Market Research, the global silicon capacitor market will be worth

$1.58 billion in 2021. It is expected to grow at a CAGR (Compound Annual Growth Rate) of 5.4% from 2022 to 2031.

Meanwhile, according to a study by Mordor Intelligence, the global MLCC market size will reach $11.63 billion in 2021 .

It is expected to grow at a CAGR of 6.03% from 2022 to 2027.