Japan's Renesas 12-inch chip production line ceased production due to fire

Japan's Renesas 12-inch chip production line ceased production due to fire

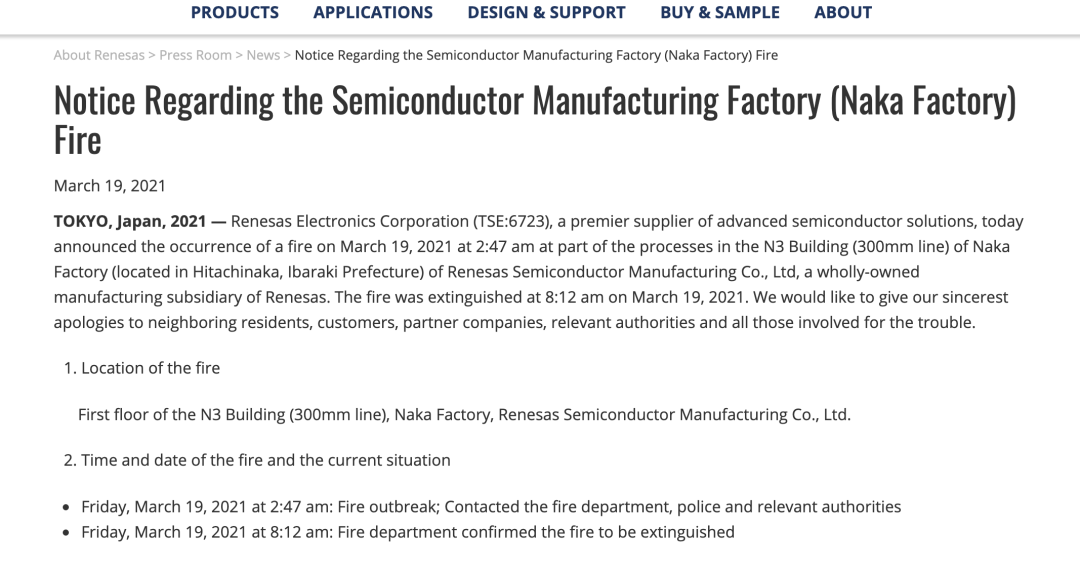

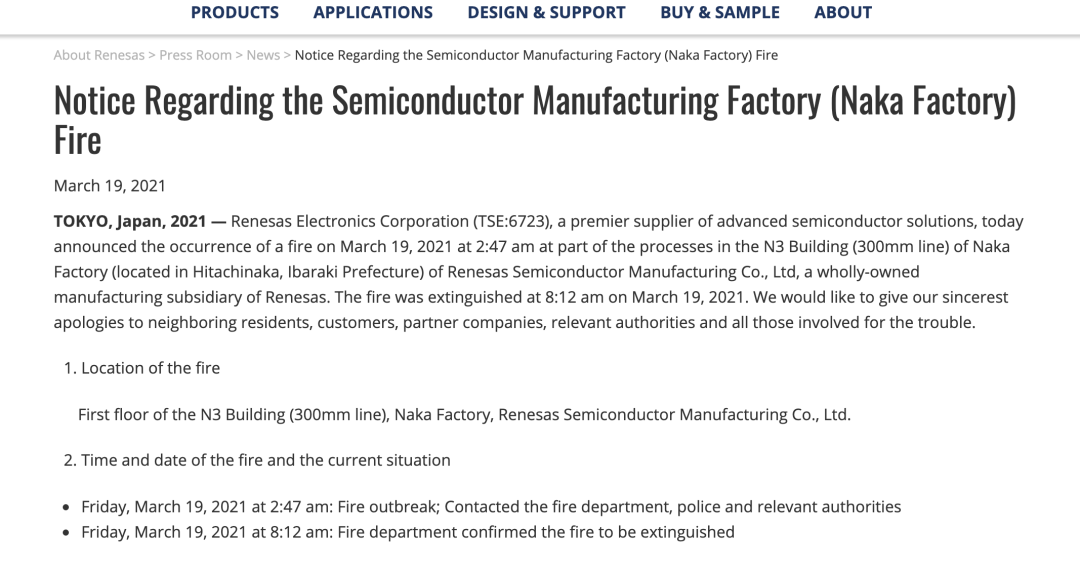

According to the situation reported on the official website of Japan’s Renesas on March 19, a fire broke out on the first floor of the N3 floor of Renesas’ NAKA factory in Ibaraki Prefecture at 2:47 am local time on Friday. The fire was confirmed to have been extinguished at 8:12. Some supporting facilities Damaged utilities.

Renesas said it is currently assessing the extent of the loss, and the production of the N3 building (12-inch chip production line) has been temporarily suspended. As for when production will resume, it needs to wait for the company's announcement. However, there were no casualties in the fire, and the 8-inch line of the NAKA factory on the N2 floor was not affected by the fire.

Picture: Renesas reports the fire situation

Source: Renesas official website

As of 11 pm on Friday, Renesas said it has not been able to confirm whether the fire point affects the safety of the clean room (the main chip production site), and it cannot enter the clean room to determine the cause of the fire. At 9 o'clock on Saturday morning, the police and fire department will conduct an on-site investigation. Renesas pointed out that once the cause and impact of the fire are determined, the company will issue an announcement.

With the rapid development of semiconductor process technology, the chip line width has entered the nanometer level, and the corresponding products have higher and higher requirements for the production environment of semiconductor products. Therefore, the operating status of the clean room system of the semiconductor purification project has an impact on the quality and pass rate of silicon chips. The impact of this is decisive. The smoke and dust brought about by the fire have greatly damaged the chip production environment.

Market worries, the lack of core car companies may increase

Although Renesas did not disclose which chips the damaged production line mainly produces, half of the company's revenue comes from the automotive market, producing various chips used in automobiles, such as those used in sensors and power units. The fire at Renesas has also caused market concerns, fearing that the lack of cores in car companies will intensify.

As early as November 30 last year, Japanese semiconductor manufacturer Renesas Electronics sent a product price increase notice to customers, the effective date of which is January 1, 2021. The notice mentioned that due to the increase in raw material and packaging costs, Renesas Electronics intends to increase the prices of some analog and power products.

Regarding the reasons for the price increase, Renesas Electronics said that the company is facing increased inventory costs and product transportation risks in the near future, which has forced the company to raise prices to ensure that these products can continue to be put into production.

Now the fire has caused the production line to stop, fearing that Renesas' production capacity will be further reduced. On the other hand, the suspension of car companies due to lack of cores is further deteriorating. In January of this year, Honda, Toyota, Nissan, Volkswagen, Ford, Sanjie and other automakers announced the suspension of some production lines. Now with the further development of the core shortage, more auto production lines are being announced.

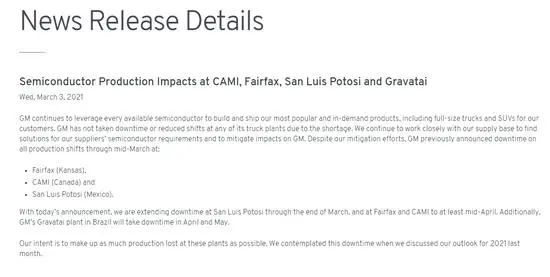

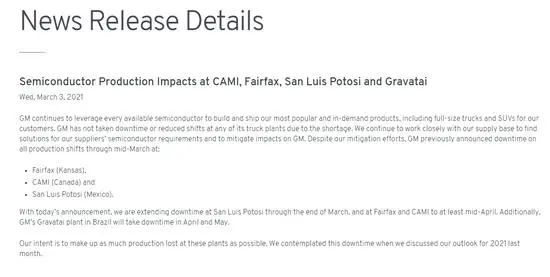

GM: Both production stoppage time and scale expansion

General Motors announced again in early March that it would extend the shutdown time of its three North American plants, and the Brazilian plant will also join the suspension of production in April.

Source: General Motors

As early as February 3, General Motors announced the closure of three factories located in Fairfax Industrial Zone, Kansas, USA; Ingersoll Rand, Ontario, Canada; and San Luis Potosí, Mexico. It was announced that the shutdown period of the three factories was extended by one month to mid-March. At the beginning of this month, General Motors once again stated that it has decided to extend the shutdown time of these three plants again. The shutdown time of the San Luis Potosí, Mexico plant will be extended to the end of March. The Fairfax Industrial Zone, Kansas, USA, and Ingersoll Rand, Ontario, Canada The plant shutdown period was extended to at least mid-April.

Honda:

Plants in the U.S. and Canada will temporarily suspend some production

Honda said on the evening of March 16 that Honda's plants in the United States and Canada will temporarily suspend part of production from March 22 to March 26. A Honda spokesperson revealed that Honda's factories in the United States and Canada stopped production for a week due to the epidemic, port congestion, chip shortages and extreme cold weather.

Toyota: 4 plants in North America will suspend partial production

According to a report from Nikkei Chinese on March 18, Toyota will partially suspend production of its 4-seater vehicle and engine plants in the United States and Mexico. Affected by the record cold wave that hit the United States in February and the large-scale power outage in Texas, the supply of resin parts and other components has stagnated, affecting production. In the automotive industry, production capacity compression caused by semiconductor shortages continues, and the current impact has expanded to resin parts.

Volvo: Will suspend or adjust production in China and the United States in March

Volvo Cars and local time said on March 17 that due to the shortage of global semiconductor chip supply, the company will suspend or adjust production in China and the United States in March. "We expect the situation to become severe in the second quarter, so we decided to take measures to minimize the impact on production, while improving the situation through daily work," Volvo said in a statement. "Volvo Cars will temporarily stop in March. Or adjust the production of some auto plants (in the United States and China)."

--End--

According to the situation reported on the official website of Japan’s Renesas on March 19, a fire broke out on the first floor of the N3 floor of Renesas’ NAKA factory in Ibaraki Prefecture at 2:47 am local time on Friday. The fire was confirmed to have been extinguished at 8:12. Some supporting facilities Damaged utilities.

Renesas said it is currently assessing the extent of the loss, and the production of the N3 building (12-inch chip production line) has been temporarily suspended. As for when production will resume, it needs to wait for the company's announcement. However, there were no casualties in the fire, and the 8-inch line of the NAKA factory on the N2 floor was not affected by the fire.

Picture: Renesas reports the fire situation

Source: Renesas official website

As of 11 pm on Friday, Renesas said it has not been able to confirm whether the fire point affects the safety of the clean room (the main chip production site), and it cannot enter the clean room to determine the cause of the fire. At 9 o'clock on Saturday morning, the police and fire department will conduct an on-site investigation. Renesas pointed out that once the cause and impact of the fire are determined, the company will issue an announcement.

With the rapid development of semiconductor process technology, the chip line width has entered the nanometer level, and the corresponding products have higher and higher requirements for the production environment of semiconductor products. Therefore, the operating status of the clean room system of the semiconductor purification project has an impact on the quality and pass rate of silicon chips. The impact of this is decisive. The smoke and dust brought about by the fire have greatly damaged the chip production environment.

Market worries, the lack of core car companies may increase

Although Renesas did not disclose which chips the damaged production line mainly produces, half of the company's revenue comes from the automotive market, producing various chips used in automobiles, such as those used in sensors and power units. The fire at Renesas has also caused market concerns, fearing that the lack of cores in car companies will intensify.

As early as November 30 last year, Japanese semiconductor manufacturer Renesas Electronics sent a product price increase notice to customers, the effective date of which is January 1, 2021. The notice mentioned that due to the increase in raw material and packaging costs, Renesas Electronics intends to increase the prices of some analog and power products.

Regarding the reasons for the price increase, Renesas Electronics said that the company is facing increased inventory costs and product transportation risks in the near future, which has forced the company to raise prices to ensure that these products can continue to be put into production.

Now the fire has caused the production line to stop, fearing that Renesas' production capacity will be further reduced. On the other hand, the suspension of car companies due to lack of cores is further deteriorating. In January of this year, Honda, Toyota, Nissan, Volkswagen, Ford, Sanjie and other automakers announced the suspension of some production lines. Now with the further development of the core shortage, more auto production lines are being announced.

GM: Both production stoppage time and scale expansion

General Motors announced again in early March that it would extend the shutdown time of its three North American plants, and the Brazilian plant will also join the suspension of production in April.

Source: General Motors

As early as February 3, General Motors announced the closure of three factories located in Fairfax Industrial Zone, Kansas, USA; Ingersoll Rand, Ontario, Canada; and San Luis Potosí, Mexico. It was announced that the shutdown period of the three factories was extended by one month to mid-March. At the beginning of this month, General Motors once again stated that it has decided to extend the shutdown time of these three plants again. The shutdown time of the San Luis Potosí, Mexico plant will be extended to the end of March. The Fairfax Industrial Zone, Kansas, USA, and Ingersoll Rand, Ontario, Canada The plant shutdown period was extended to at least mid-April.

Honda:

Plants in the U.S. and Canada will temporarily suspend some production

Honda said on the evening of March 16 that Honda's plants in the United States and Canada will temporarily suspend part of production from March 22 to March 26. A Honda spokesperson revealed that Honda's factories in the United States and Canada stopped production for a week due to the epidemic, port congestion, chip shortages and extreme cold weather.

Toyota: 4 plants in North America will suspend partial production

According to a report from Nikkei Chinese on March 18, Toyota will partially suspend production of its 4-seater vehicle and engine plants in the United States and Mexico. Affected by the record cold wave that hit the United States in February and the large-scale power outage in Texas, the supply of resin parts and other components has stagnated, affecting production. In the automotive industry, production capacity compression caused by semiconductor shortages continues, and the current impact has expanded to resin parts.

Volvo: Will suspend or adjust production in China and the United States in March

Volvo Cars and local time said on March 17 that due to the shortage of global semiconductor chip supply, the company will suspend or adjust production in China and the United States in March. "We expect the situation to become severe in the second quarter, so we decided to take measures to minimize the impact on production, while improving the situation through daily work," Volvo said in a statement. "Volvo Cars will temporarily stop in March. Or adjust the production of some auto plants (in the United States and China)."

--End--